|

|

|

How to: Stitch and Glue building method Stitch and glue building method:

Below is a brief overview of the materials and process. The following is merely our recommendations based on our experience and not meant to be implied as being the best or only way to do things. Any recommendations we make for products in this guide are not paid advertisements. They are simply things we found helpful in our own experiences. Wood The recommended wood to use for a stitch and glue kayak is BS1088 3mm or 4mm thick Okoume. This is marine grade African mahogany plywood. People might use 4mm for the hull and 3mm for the deck. Some choose to use 3mm for the whole thing as to reduce the overall weight of the boat a bit but we do not recommend doing so. We prefer the whole thing in 4mm. Epoxy There are many good epoxies out there. System Three and West System are two very good ones. www.jamestowndistributors.com has a nice selection of epoxy and many other things for boat builders. The more you know when it comes to epoxy and how to handle it the better off you will be. The epoxy you will want to use will be a two part system. The resin (part A) and the hardener (part B). BE SURE TO LOOK AT THE MIXING RATIO FOR THE RESIN AND THE HARDENER. The mixing ratio is crucial. Any other mistake you make while building can be fixed with sand paper or epoxy or fiber glass or a little TLC. But, if you get the mixing ratio wrong while scarffing the joints or wetting out the fabric, you are in big trouble! If not done correctly, the mix (if it even cures) will be too brittle or not strong enough to be safe and will need to be undone and fixed. The temperature of the environment you are working in will affect the cure times for the epoxy. Warmer temps will result in faster curing times. The epoxy reaction between the resin and hardener is exothermic meaning it produces heat. Since heat affects the cure time and the curing process produces heat, the less surface area the mix has the shorter the working time will be. This is because less surface area equals less heat dissipation. Another thing to know about epoxies is there are different types of hardeners; fast, medium and slow. These are used in different temperatures and have different working times. For a complete guide to using epoxy please download The Epoxy Book from System Three. Fiber glass You can use 4 oz. or 6 oz. fiber glass cloth for glassing the insides of the shell and the deck but we don’t recommend using 4 oz. cloth for the outside hull simply because it will be less durable than a heavier 6 oz. cloth. It would be a real shame to run your boat up on a rock and have it put a large gash deep in your hull. Fiber glass tape is a narrow cloth with woven edges to avoid unraveling. For the seams you can use 3 or 4 inch fiber glass tape. Varnish

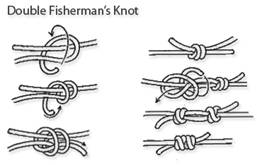

Straps It is very important not to use nylon straps to secure your hatch covers. Nylon tends to stretch when wet and also rots after time when exposed to the elements. Polypropylene webbing will not stretch and is water/rot resistant. Visit www.strapworks.com for webbing, plastic slides and buckles.

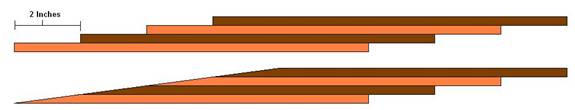

Scarffing plywood

sheets together Scarffing is a technique by which two sheets of plywood are connected to create one long sheet. This can be done many ways but our personal favorite is simply to stack the plywood sheets with a two inch space between the edges and use a belt sander to sand them down smooth. Be sure to sand evenly as to avoid a wavy edge. Once the edges are all uniformly sanded down they are ready to be put together with epoxy.

Cutting out paper plans

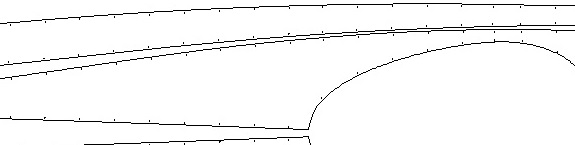

Take your time to cut the paper plans out carefully. While cutting out the plans remove excess paper and tape the paper panels down to secure them to the plywood to prevent shifting. If the paper bends and shifts on the plywood it will cause incorrect panel shaping when cutting the wood. Do not rush through this step. Drilling out stitch

holes Our plans have predetermined stitch points marked to help ensure accurate alignment of panels during assembly. This is critical in producing a straight and properly assembled kayak. Under Edit/Preferences in the software you have the option to specify how far apart you wish to have the stitch marks in the full size plans. The default is 4 inches. You also have the ability to set the stitch mark length which has a default setting of .25 inches. Before cutting out the panels drill a hole through the end of each stitch mark inside the panels. Drilling out the stitch marks before cutting is important because the paper usually gets torn up and ruined during the cutting stage.

Cutting out wood

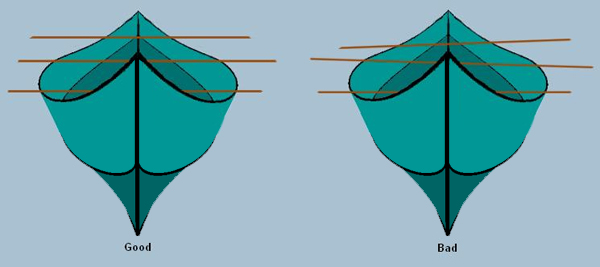

panels It pays to take your time during this step. Some builders like to use a Japanese hand saw for this step because it gives you good control. Personally, we like the saber saw with a metal cutting blade. If you use a saber saw, do not use a blade made for cutting wood; the teeth are too large and will tear up the edges of your wood panels. Remember, you must cut through two layers of plywood to create two sets of panels (port side and starboard side). This will ensure that the panels are identical and will help keep the boat straight and aligned correctly. While not unfixable, mismatched panels are a bit of a pain to deal with. You may also want to slightly bevel the inside edges of each panel to allow them to fit together a little better. Just be sure to double check which side is the inside of each panel before cutting the bevels. Wiring the panels

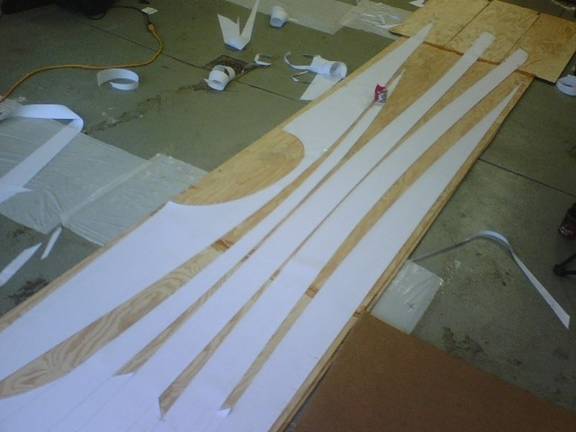

together

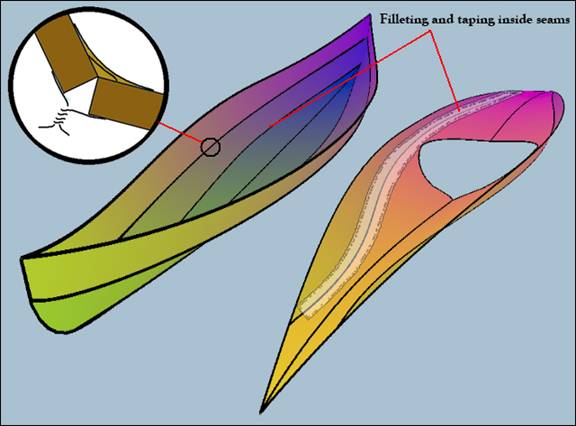

Notice the sticks sitting next to the hull. They were used to ensure proper alignment the hull panels. This was done by laying them perpendicular across the hull and comparing them to each other. If they all appear parallel then the alignment is good. Filleting and

taping seams After the deck and hull are stitched together and you have ensured proper alignment of the panels, you will begin using epoxy mixed with a filler to glue the seams together. In this step you will be filling the seams from the inside of the boat with an epoxy/filler mixture. The filler is used to thicken up the epoxy for strength and prevents the epoxy from running. There are several fillers available but the one we prefer to use is wood flour or very fine saw dust. Mix the filler with epoxy until it does not run but also does not appear dry. Only work with small amounts of epoxy when filleting the seams. This will avoid waste, haste and excess epoxy on the seams. Keep the seams neat by using a plastic spreader instead of your fingers and wear strong disposable gloves. After the seams are filled and the mixture is still wet you will apply the fiber tape to the seams. Wet whatever portion of the tape remains dry with regular epoxy to ensure the tape’s adherence to the wood.

For a complete understanding of how to use epoxy and what to use for epoxy filler, please download The Epoxy Book by System Three. After the inside fillets dry you will cut off all the wire twists on the outside of the boat and fillet the seams on the outside. When the seams are totally dry, it will be time for sanding.

Sanding Sanding

Sanding If you are the type of person who hates sanding, don’t build a kayak. You will be sanding the entire time from making scarf joints to sanding the entire surface area the deck and hull to wet sanding the finish (and much more). There will be no shortage of sawdust in your workspace so be safe. Use proper ventilation and wear breathing masks. Although some sanding will have to be done by hand, an electric palm sander is great for most of the sanding that you will be doing. Hatches

Glassing Before applying the fiber glass to the boat, it is recommended that you apply a thin coat of epoxy to the entire wood surface and let it set. This allows the wood to absorb the epoxy which will prevent further absorption after the glass is wetted out (to ‘wet out’ the glass means to saturate it with epoxy, bonding it to the wood). If this is not done prior to glassing, then the wood could absorb the epoxy out from under the glass creating air pockets underneath. Even if visible air pockets are not present, there could be weak spots in the wood/glass bond that could delaminate under strain. Such delamination would compromise the structural integrity of the craft possibly making it unsafe. Allow the glass to lay spread out on the surface overnight to allow the folds in the glass to settle to the shape of the kayak. Also, be careful not to crease the cloth in any way, it is delicate and imperfections will be visible later on. When applying the epoxy to the cloth, use either the flat side of a plastic spreader or an epoxy roller. Remember, working with small amounts of epoxy is very important during this step. We would not recommend mixing more than 4 to 6 oz at a time. Apply an even amount across the surface of the cloth causing it to become transparent. Work out any air pockets and remove excess epoxy as to not allow the cloth to float off of the wood. Excess epoxy adds weight but does not add strength to your boat.

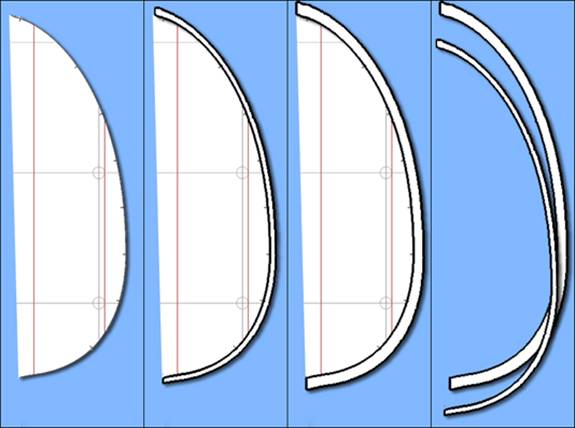

Apply glass to both the inside and outside of the deck and hull. When doing the insides, be careful not to allow the epoxy to pool at the bottom of the hull and the upside down deck. This can be avoided by using only enough epoxy to saturate the cloth. Remember, if you need to add more to fill out the weave, you can do so later on. After the epoxy has set, trim off the excess cloth around the edges with a razor blade. Cockpit Coaming At the time of this writing, Stitch–N- Glue Pro does not provide forms for the cockpit coaming. It is possible however to use the cockpit cut out portion of the deck panel from the original plans to obtain the shape of the curve of the coaming. Using this curve you can then expand it ½ inch and then 1 inch to get the shapes of the coaming pieces. Trace and cut out the shapes onto poster board.

Connecting Deck and

After the inside seams are set, remove any straps and tape that were used to hold them together. Now fillet the outside of the deck/hull seam to complete the connection.

You will need to sand down the newly filleted seams and an overall light sanding to get the surface ready for varnish. Varnish

End Pours The purpose of the end pours is to strengthen the ends, secure the deck to the hull and to provide reinforcement for hand loops (for carrying the boat). You will only need half a cup or so to do the job on each end. Mix the epoxy with micro-balloons to the point where it’s thickened up but still able to run. Stand the kayak on its end and pour the mix into it allowing it to settle at the tip. Once set turn the kayak over and repeat on the other end. Inside the cockpit

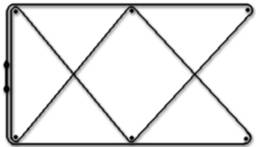

Deck Rigging

Congratulations! You have designed and built your very own work of art. Go show it off and enjoy!!!

|

|

|

|

![]()